In business, you’re usually equal parts discovering problems AND using creative problem solving to address the issues. Yet, a client approached us to design and conduct a cross-operation innovation strategy engagement focused solely on identifying problems. They wanted to leave the creative problem solving for later.

The innovation opportunity in this example? A recently-opened production operation that included multiple natural breakdown points:

- Two companies partnering in a long-term provider-customer manufacturing operation

- A production facility located outside the US with language and culture barriers

- New, non-US leadership working with the seasoned, US-based team that stood up the new operation is still involved in oversight

The client’s objective was to create a process-based exploration of pain points, challenging team members’ blinders, complacency, and reluctance to push for dramatic improvements.

Trying Painstorming Before Creative Problem Solving

The client dubbed this a painstorming process. While painstorming is a thing, the structure and specifics weren’t aligned with the client’s objectives. Instead, we took a different approach.

We used a pre-workshop outreach soliciting input on opportunities and pain points. We coupled this with multiple in-person workshop exercises to identify and prioritize more than one hundred pain points.

If you need to heavy-up on problem identification as part of your innovation strategy, here were some of our learnings about the process.

Identifying Pains

1. Ask people about pain points individually

Problems are sensitive topics; they are ripe for team member defensiveness, reluctance to fully share, and a hesitancy to come across as negative. Because of this, we used online questions to individually solicit pain points and opportunities. The respondents included in-person participants plus frontline employees, executives, and stakeholders. We created a Spanish version of the survey to increase in-country employee participation.

The survey analysis yielded ninety ares to address:.

- The Spanish language surveys revealed cultural and management problems no other surveys discussed.

- Executive responses highlighted disconnects in goal setting and expectations.

- Stakeholder comments revealed focus areas among the meeting participants

The varied responses shaped the workshop.

2. Invite People with Fresh Eyes

The client invited stakeholders to bring people from their areas who were not involved in creating and running the operation. The objective? Include people with functional experience who were not clouded by previous participation. These fresh eyes proved valuable because they weren’t influenced by direct ownership or implementation biases.

3. Start with the Obvious

Identifying numerous pain points upfront, we prioritized each one. We accomplished this through identifying the potential impact of addressing a pain point versus the ability to make headway on it. We split the group in two. Each group performed the same prioritization exercise. While there were many agreement areas, differing perspectives fueled a full morning of discussion and reconciling the groups’ perspectives. This led to aligning many closely-related pain points. The net of it was settling on fifty problems to potentially tackle.

4. Explore the Situation Closely

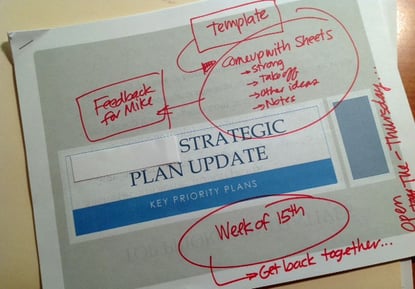

The in-person workshop didn’t take place at the actual facility we were addressing. Our client had taken photos of the operation from the ground and from the sky via a drone. He shared the photos plus a worksheet we developed for noting pain points based on:

- What they KNEW were problems

- Could SEE or SUSPECTED as issues from the photos

- WONDERED about as potential challenges.

This exercise identified additional pain points, especially for participants who hadn’t been onsite recently.

5. Use an External Perspective

We incorporated external research on typical breaking points in manufacturing partnerships, plus well-performing, overlooked areas that can become vulnerabilities into additional in-person exercises. While these yielded fewer new pain points, several emerged that were significant and had gone unmentioned previously.

6. Go Deeper and Document

After selecting three major issues and a dozen quick wins, the group completed 5-Whys exercises to probe for underlying issues. Additionally, they completed assessments on each problem. This included a problem statement, expectations for what the solution would include, known barriers and constraints, and the people needed to address the issue.

7. What We’ll Take Away for Next Time

Given the operation’s immaturity, there weren’t sufficient objective metrics to analyze. That led to more opinions and experience than quantitative data driving the agenda. We also had wanted to set a foundation of positive things happening and create a stronger cross-participant sense of the shared opportunity. This didn’t happen effectively. While we excelled at identifying problems, walking in and meeting most of the participants for the first time created an initial environment that made highlighting positives a challenge.

Feeling the Pain?

If you are facing a turnaround with more problems than successes, focusing exclusively on identifying pain points may be a natural step. Even so, it’s vital to recognize the wins and create a clear path toward fixing pain points.

Want to move quickly to address pain points you see, suspect are there, or fear are going unnoticed? Contact us, and let’s talk about customizing this approach for you before you turn to creative problem solving. – Mike Brown